-

-

-

-

-

Investor Relations

-

Rejuvenating the country by industry and making career more successful

智能制造一体化 · 解决方案提供商

Public notice

Dear all customers and partners:

This website is our company only official English website.

The address is: http://en.ntgszk.com .

Our company is an integration of manufacturer and seller.

The export trade information as below:

Sales email : chenjuan@ntgszk.com

Sales contact phone: 18260595048

It is hereby announced!

Nantong Guosheng Intelligence Technology Group .Co.,Ltd

2023.07.18

Guosheng Group

Intelligent manufacturing integration · Solution provider

Nantong Guosheng Intelligent Technology Group Co., Ltd. was established in 1996. It is a national high-tech enterprise, a national specialized and innovative small giant enterprise, and an excellent private enterprise in Jiangsu Province. Has been awarded multiple times as one of the top 30 enterprises in China's machine tool industry, one of the top 10 enterprises in terms of economic benefits, and one of the top 10 enterprises in terms of product quality......

Industry Experience

China Machine Tool Industry

Over 10 years employees

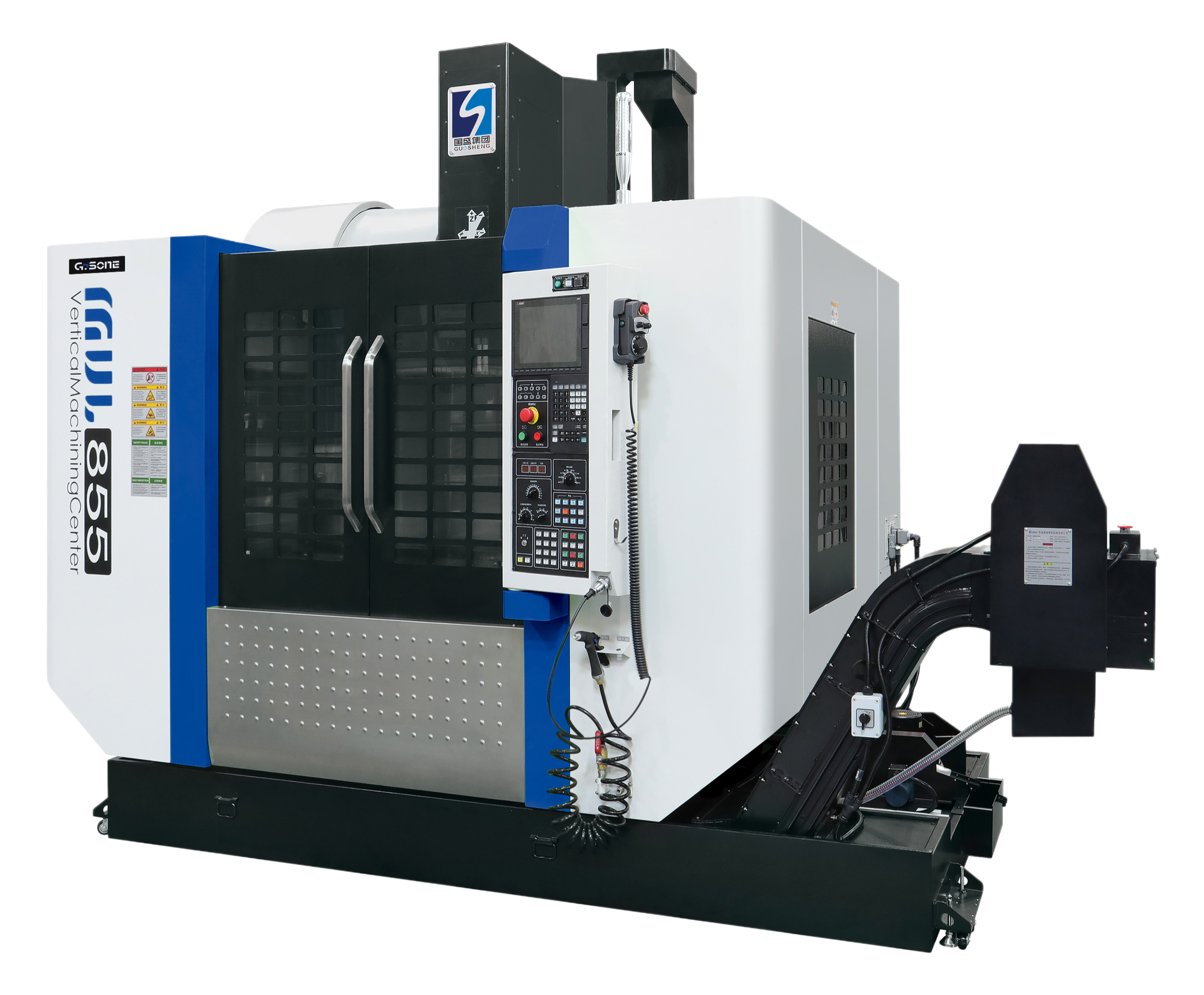

Vertical Machining Center

In addition to the processing characteristics of the vertical machining center, optimization designed the configuration and structure of the product processing industry for high speed and high precision demand.

More ⇀Gantry Machining Center

Gantry Machining Center series, are widely used in civil aviation, automotive, precision mold and parts processing industry, providing reliable performance of the mechanical system and a variety of selective software interface, to completely realize the dream of high precision.

More ⇀Horizontal Machining Center

Horizontal machining center can automatically exchange the tool, can be a clamping four face milling, drilling, reaming boring, twisting, tapping and other processes when processing. The structures of machine tool have strong rigidity, large formation, high precision, suitable for a variety of heavy cutting, high precision machining fields, ensuring high efficiency and high precision single piece or small and medium-sized batch product processing needs.

More ⇀Horizontal boring and milling machining center

It use Mihanna castings, integrated casting, which wear resistance through stress elimination treatment, so that it can achieve high shock resistance and its shock absorption capacity is higher than ordinary cast iron, improving the stability of the machine tool. What’s more, each shaft of the oil and water are recycled to avoid pollution problems, in line with the requirements of environmental protection. The axial position feedback adopts absolute optical ruler, which is precisely determined at each processing point. Because of absolute optical ruler, it can avoid the step of return to zero.

More ⇀Mold machining center

In addition to the processing characteristics of vertical machining center, mold machining center optimizes the design according to the characteristics of the mold processing industry in the configuration and structure. It can meet the requirements of high precision, high finish and low thermal extension in mold contour processing.

More ⇀CNC Lathe

CNC Lathes are mainly used for shaft parts or disk parts of the inner and outer cylindrical surface, any cone Angle of the inner and outer conical surface, complex rotary surface and cylindrical, taper thread machining, and can cut, drill, ream and bore.

More ⇀Five axis linkage machining center

● Five-axis simultaneous and full-closed loop control, ensure it is suitable for processing complex surfaces of precision molds. ● Z oriented box in box type symmetric structure ensures balanced cutting stress, and slight thermal deformation. ● The screw nut is cooled to effectively restrains thermal extension. ● With German KESSLER AC swinging head and tuning fork type structure, AC axis are driven by torque motor.

More ⇀Intelligent automated production line

Guosheng Group has established a perfect and fast response service system. It covers pre-sale, in-sale and after-sale services, and provides customers with professional and standardized services in rapid response to protect customers' rights and interests. The company will uphold the "Let the customer worry-free" principle of service so that customers can always enjoy professional quality service.

More ⇀Vertical Machining Center

Gantry Machining Center

Horizontal Machining Center

Horizontal boring and milling machining center

Mold machining center

CNC Lathe

Five axis linkage machining center

Intelligent automated production line

Guosheng Group provides you with intelligent solutions.

Service Hotline

Business Hotline

Nantong Guosheng Intelligence Technology Group Co., LTD

Address: no.2 Yongtong road ,gangzha economic and technological development zone, chongchuan district,nantong city, Jiangsu province

Fax: 86-513-85603916

E-mail: gszk@ntgszk.com

Copyright © 2023 Nantong Guosheng Intelligence Technology Group Powered by 300.cn | SEO | Business license